What caused the Deepwater Horizon disaster?

Posted by aeberman on May 21, 2010 - 10:28am

Topic: Geology/Exploration

Tags: deepwater horizon, gulf of mexico oil spill [list all tags]

Topic: Geology/Exploration

Tags: deepwater horizon, gulf of mexico oil spill [list all tags]

Author’s Note: I am grateful to the many drilling and completion engineers that consulted with me on this post to arrive at plausible explanations and interpretations of what happened in the final hours on the semisubmersible drilling rig Deepwater Horizon in the Gulf of Mexico. The analysis that follows is based on these discussions as well as my own 32 years of experience as a geologist working in the oil and gas industry.

It is early in the process of discovering what really happened. Because of the gravity and potential impact of this disaster on the nation and my industry, however, I wanted to provide an early and more investigative perspective than much of what has appeared in the media to date. The risk, of course, is that more information will invalidate some of what follows. I, therefore, wish to clarify that this is a fact-based interpretation of what may have happened on the Deepwater Horizon on April 20, 2010 but, in the end, it is an interpretation. - Art Berman

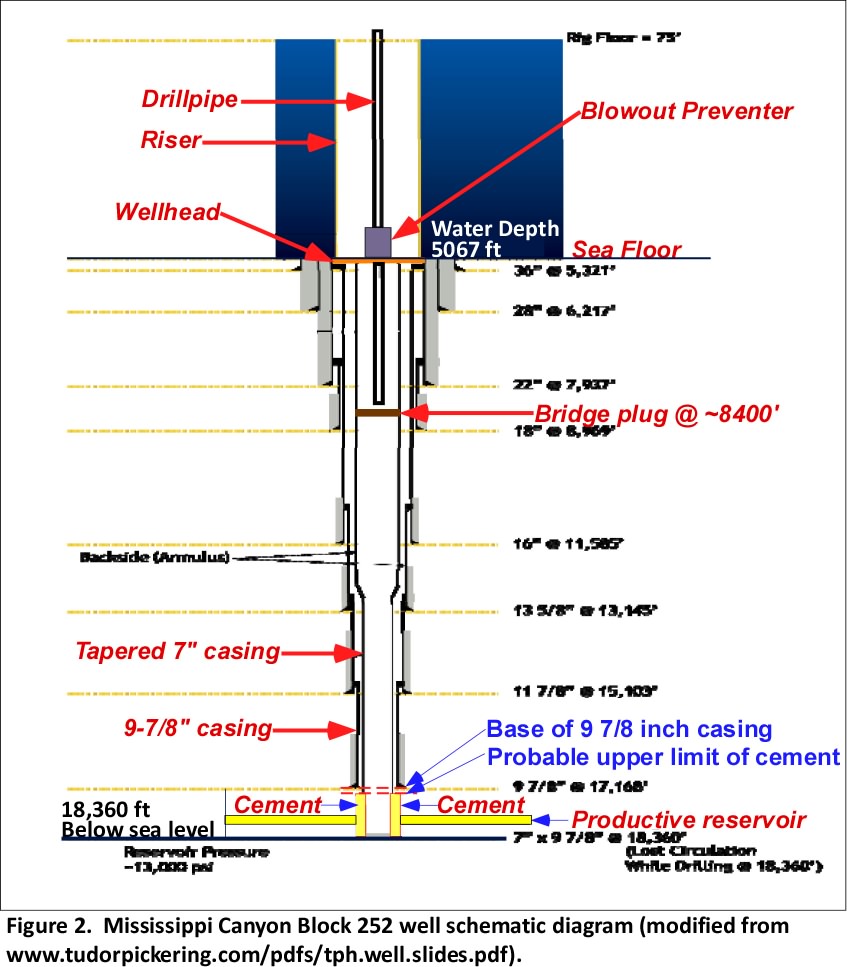

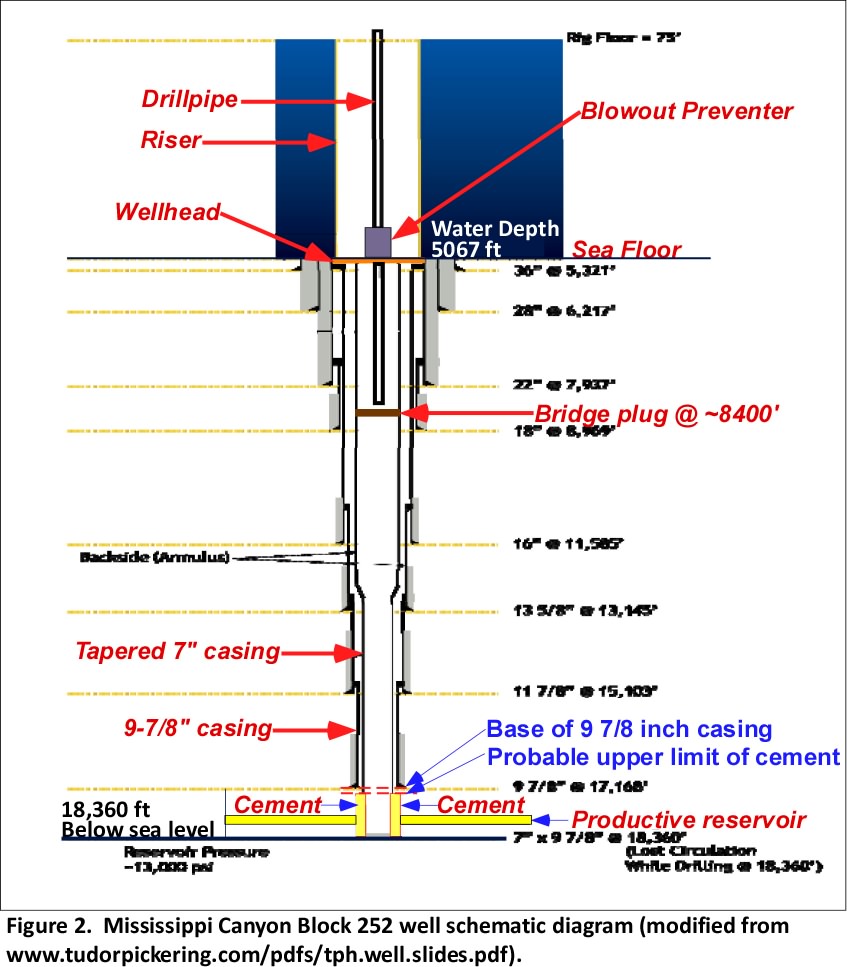

The blowout and oil spill on the Deepwater Horizon in the Gulf of Mexico was caused by a flawed well plan that did not include enough cement between the 7-inch production casing and the 9 7/8-inch protection casing. The presumed blowout preventer (BOP) failure is an important but secondary issue. Although the resulting oil spill has potentially grave environmental implications, recent efforts to limit the flow with an insertion tube have apparently been effective. Continuous efforts to slow or stop the flow include drilling two nearby relief wells that may intersect the MC 252 wellbore within 60-90 days.

It is early in the process of discovering what really happened. Because of the gravity and potential impact of this disaster on the nation and my industry, however, I wanted to provide an early and more investigative perspective than much of what has appeared in the media to date. The risk, of course, is that more information will invalidate some of what follows. I, therefore, wish to clarify that this is a fact-based interpretation of what may have happened on the Deepwater Horizon on April 20, 2010 but, in the end, it is an interpretation. - Art Berman

The blowout and oil spill on the Deepwater Horizon in the Gulf of Mexico was caused by a flawed well plan that did not include enough cement between the 7-inch production casing and the 9 7/8-inch protection casing. The presumed blowout preventer (BOP) failure is an important but secondary issue. Although the resulting oil spill has potentially grave environmental implications, recent efforts to limit the flow with an insertion tube have apparently been effective. Continuous efforts to slow or stop the flow include drilling two nearby relief wells that may intersect the MC 252 wellbore within 60-90 days.

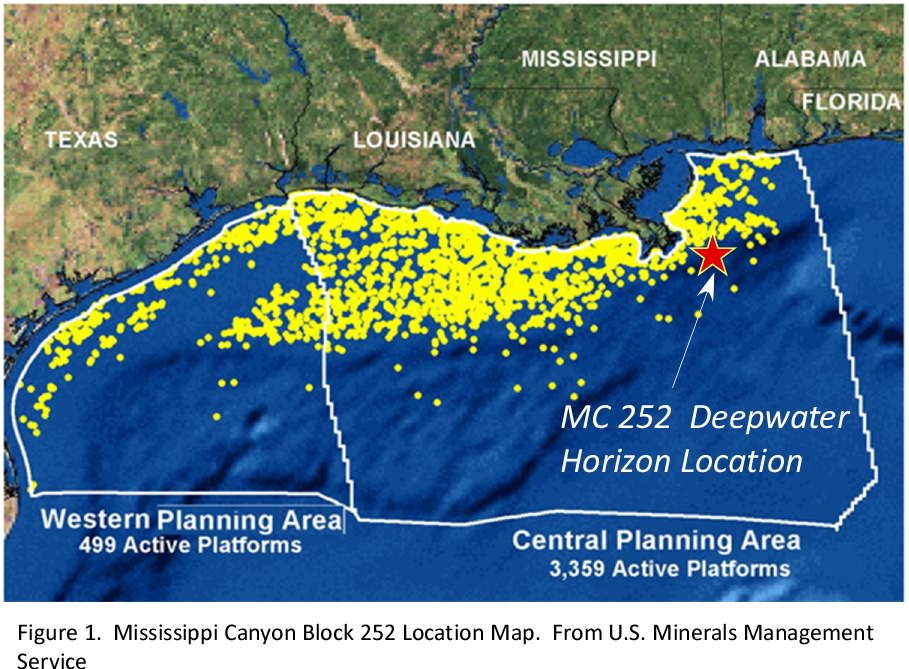

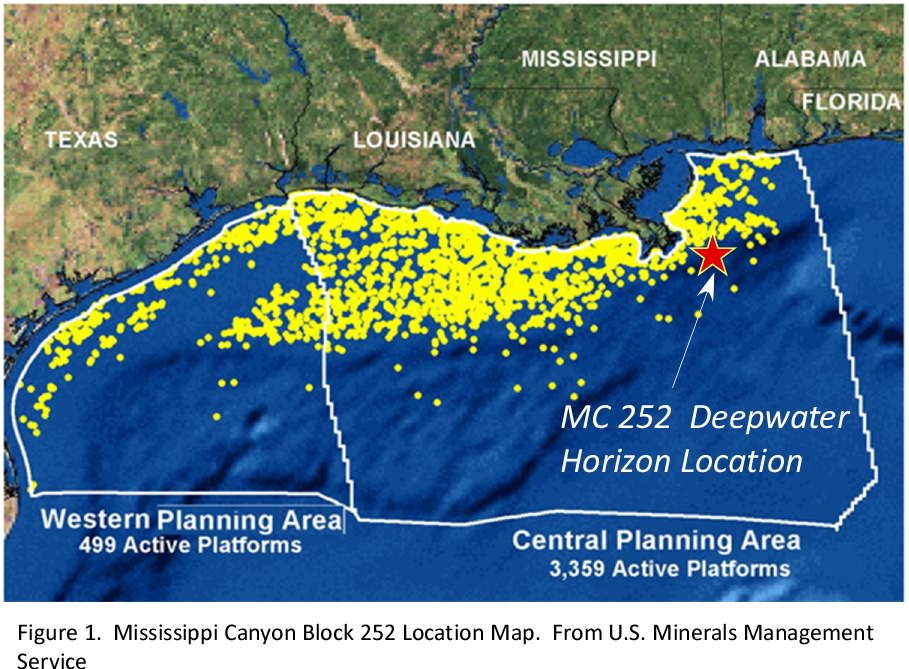

On April 20, 2010, the crew of the Deepwater Horizon was preparing to temporarily abandon BP’s “Macondo” discovery well in Mississippi Canyon (MC) Block 252 (Figure 1).

In a few hours, they would have been ready to move the drilling rig off location so that a completion rig could move on. At about 10:00 p.m., the rig unexpectedly began to shake and a loud surging noise was accompanied by natural gas, drilling mud and sea water that shot high above the floor of the drill ship. The gas exploded and the rig was engulfed in flames. A second explosion followed and the electricity went out. Eleven men died instantly and 115 others rushed to the lifeboats or jumped into the Gulf of Mexico. This all happened so fast that those who died probably had no time to understand what was happening. Two days later, the Deepwater Horizon sank to the bottom of the Gulf of Mexico, and oil has been spilling into the Gulf at rates of at least 5,000 barrels per day since then(there are 42 gallons in a barrel).

The MC 252 well is located in 5,067 ft of water about 50 miles from the coast of Louisiana. The total depth of the well was 18,360 ft below sea level (13,293 ft below the sea floor). This is not an unusually deep well nor was it drilled in exceptionally deep water compared to many other wells in the Gulf of Mexico. The Gulf drilling depth record was set earlier this year at more than 30,000 ft below the sea floor (The Oil Drum, January 18, 2010: http://www.theoildrum.com/node/6135#more), and the current water-depth record of 10,011 ft was set in 2003 (http://www.deepwater.com/fw/main/Home-1.html).

Much information has surfaced since the accident through congressional and Mineral Management Service (MMS) hearings, public statements from the companies involved and, on May 16, a feature report on CBS Television’s Sixty Minutes program. Most of this information comes from eye-witness accounts by people on or near the Deepwater Horizon at the time of the blowout.

I consider most of the publicly available accounts so far to be potential hearsay although they probably contain some good observations and elements of truth. I discount the value of the testimonials chiefly because none of these people were on the rig floor at the time of the blowout. In addition, the only people who have a comprehensive and fact-based understanding of the events leading to the accident are either sequestered by the companies involved or are dead.

2. Only 51 barrels of cement were used according to the well plan. This was not sufficient to ensure a seal between the 7-inch production casing and the previously cemented 9 7/8-inch protection casing (Figure 2).

3. Mud had been lost to the reservoir while drilling the bottom portion of the well (this is called “lost circulation”). It usually indicates good reservoir quality, an interval of lower pressure or both, and can result in an enlarged wellbore or “washout”. The significance of this is that it might have been difficult to create a good cement seal between the casing and the formation. It also would have been impossible to ensure the effectiveness of the cement seal without running a cement-bond log, and this was not done.

4. The cement contained a nitrogen additive to make it lighter so that it would flow more easily and better fill the area between the casing and the lost circulation-washout zone. This also may have decreased its sealing effectiveness. Gas from the reservoir may have further diluted the viscosity of the cement.

5. While waiting approximately 20 hours for the cement to dry on April 20, the crew began displacing the drilling fluid (“mud”) in the wellbore and riser with sea water before setting a cement plug and moving off location. This mud was pumped into tanks at the surface, and then onto a platform supply vessel alongside the rig (whose captain gave testimony before an MMS hearing last week).

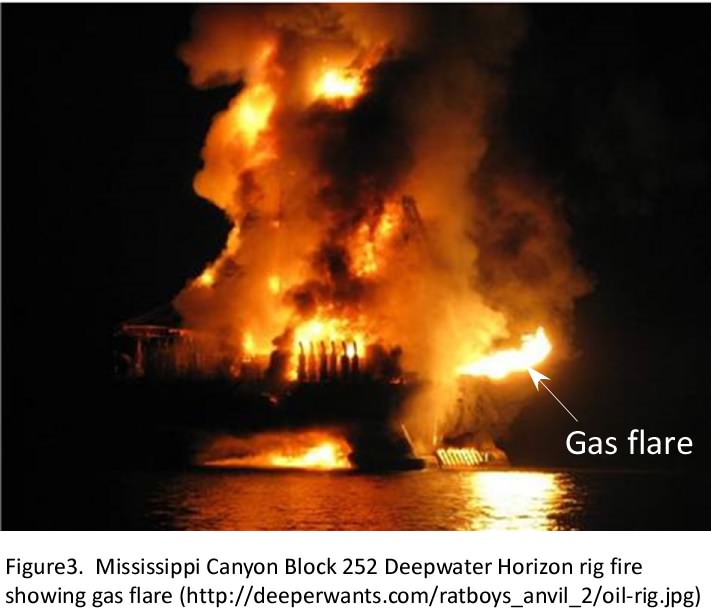

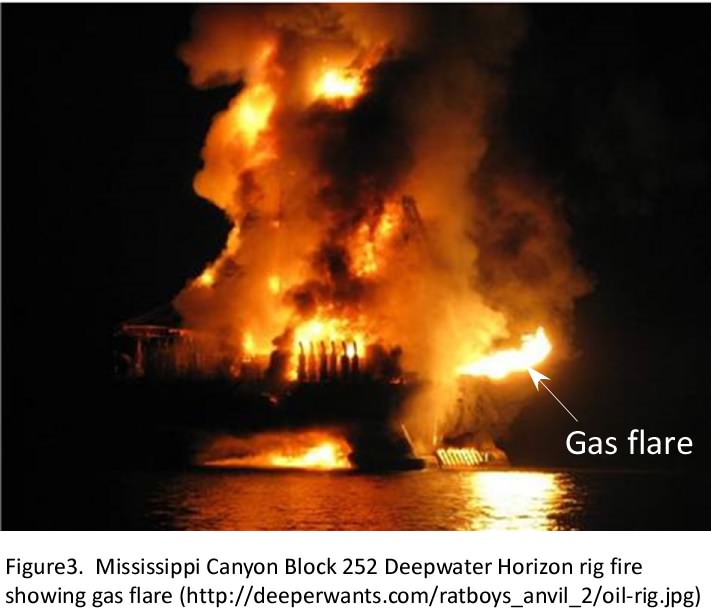

6. Sea water is much lighter than drilling mud so there was less downward force in the wellbore to balance the flow of gas from the reservoir. The drilling supervisors knew that there was gas in the drilling fluid because a gas flare can be seen in photos probably coming from a diverter line in the riser (Figure 3).

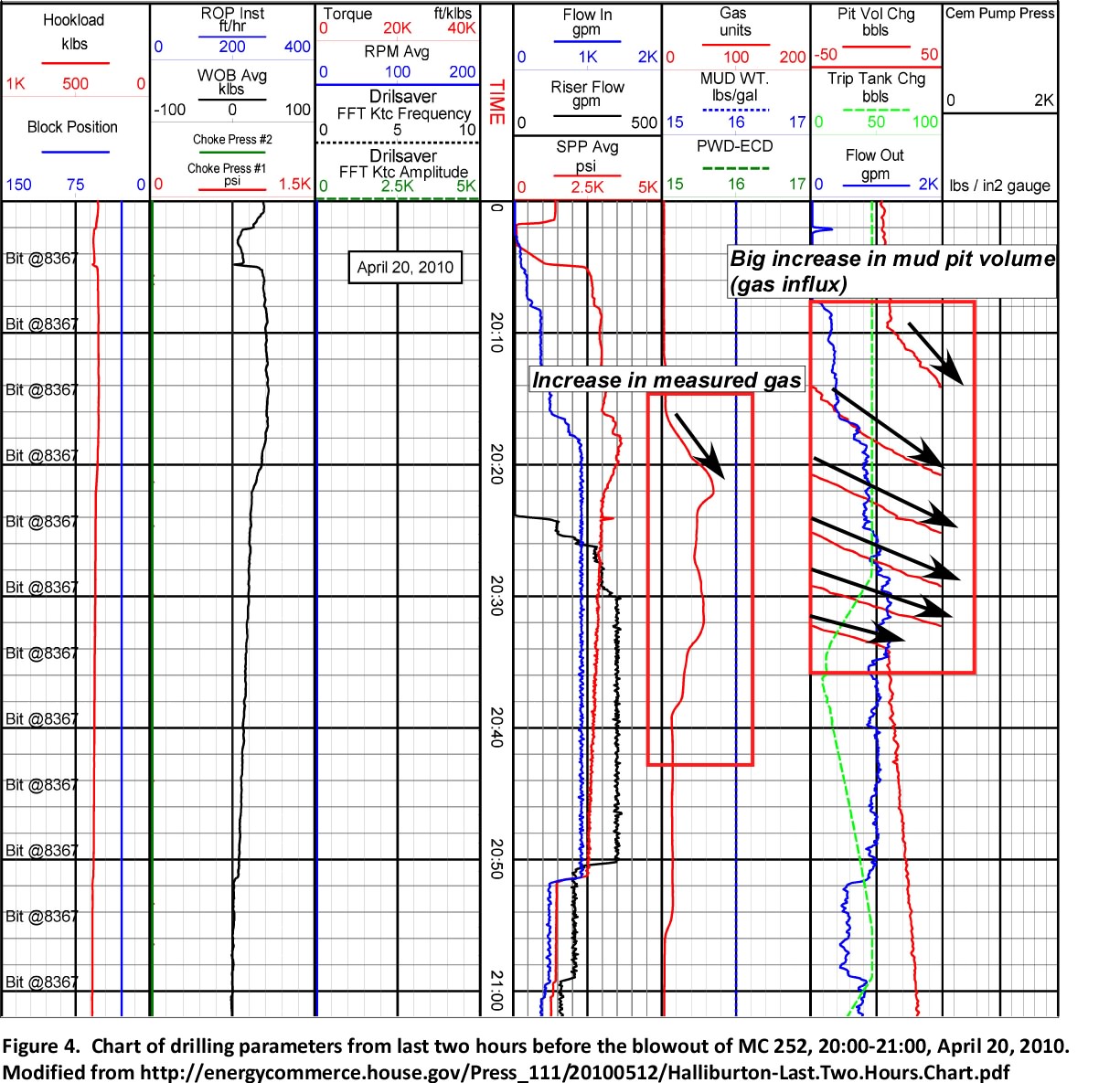

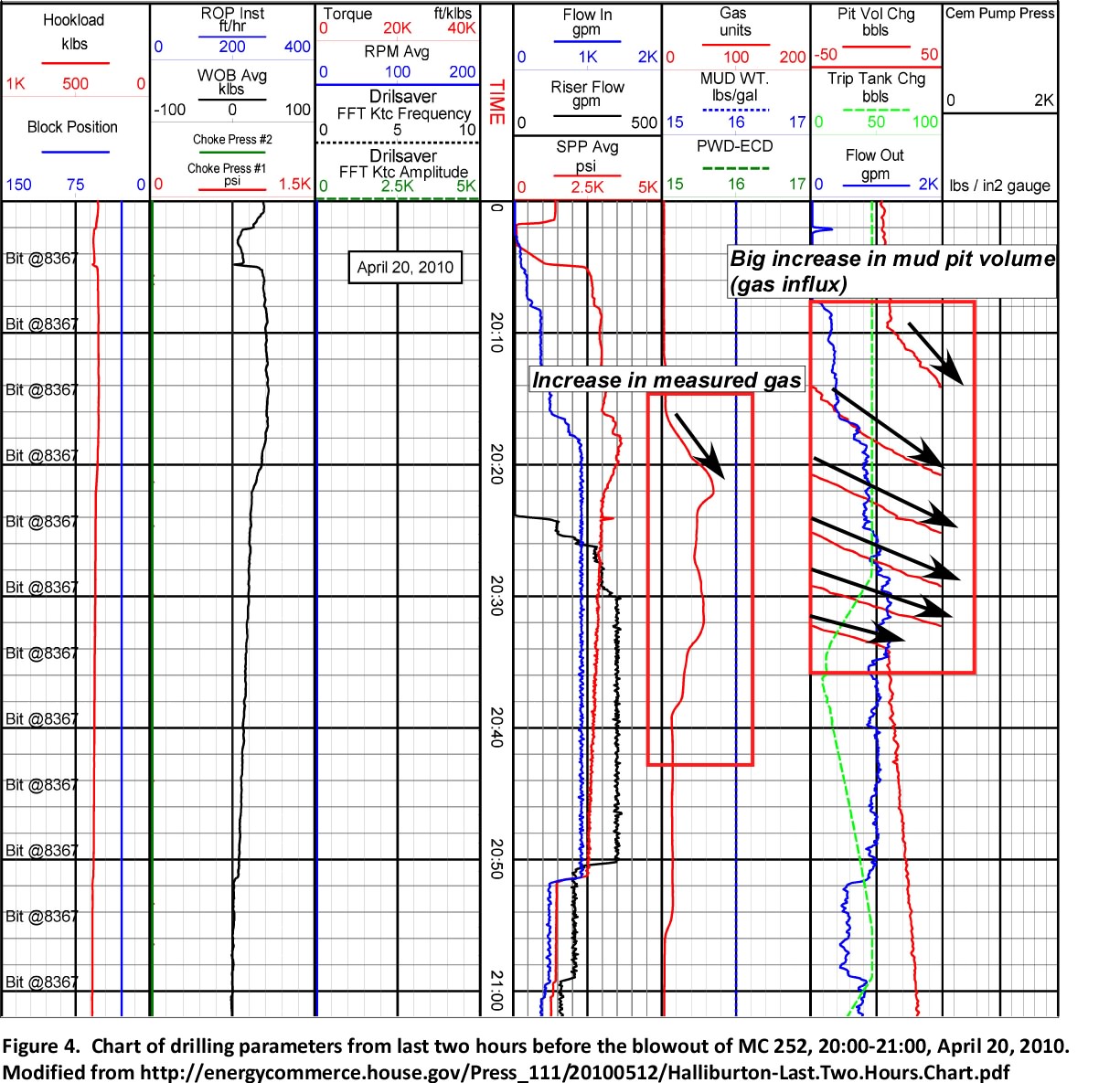

7. The chart of drilling parameters for the last two hours before the blowout suggests that the riser and upper 3,000 ft of the wellbore were fully displaced with seawater by 20:00 on April 20, and the crew was circulating the drilling fluid Beginning 10 minutes later, at 20:10, the mud pit volume began to increase probably because of gas influx (Figure 4). The volume increased so much, that the recorder re-zeroed four times. When the crew stopped pumping at 21:08, the mud pit volume decreased and this may have alleviated some concern about gas influx.

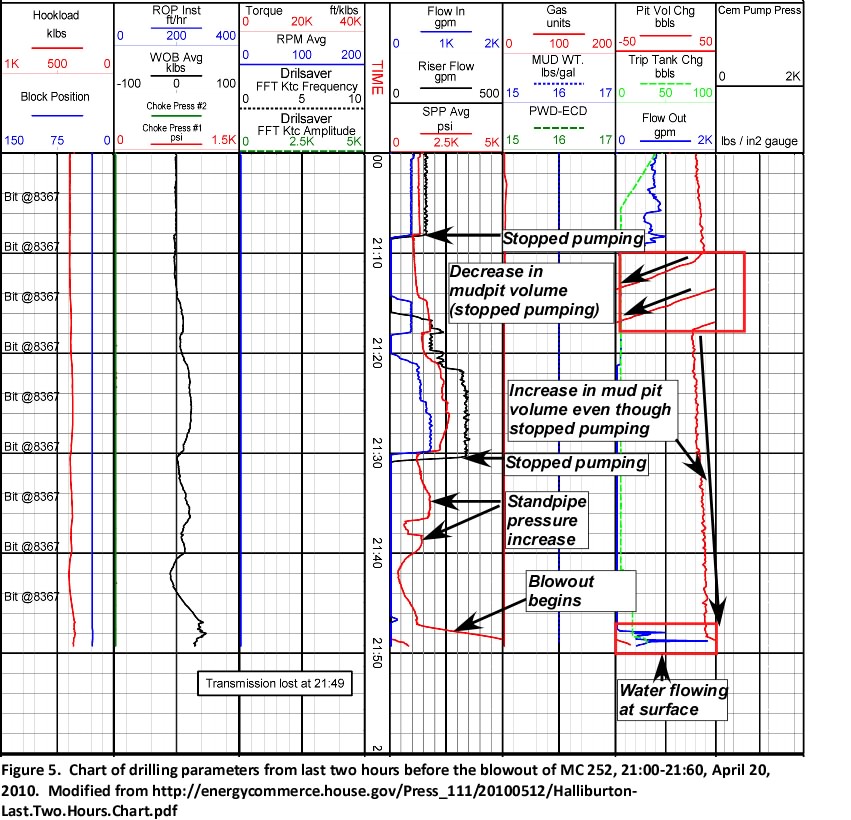

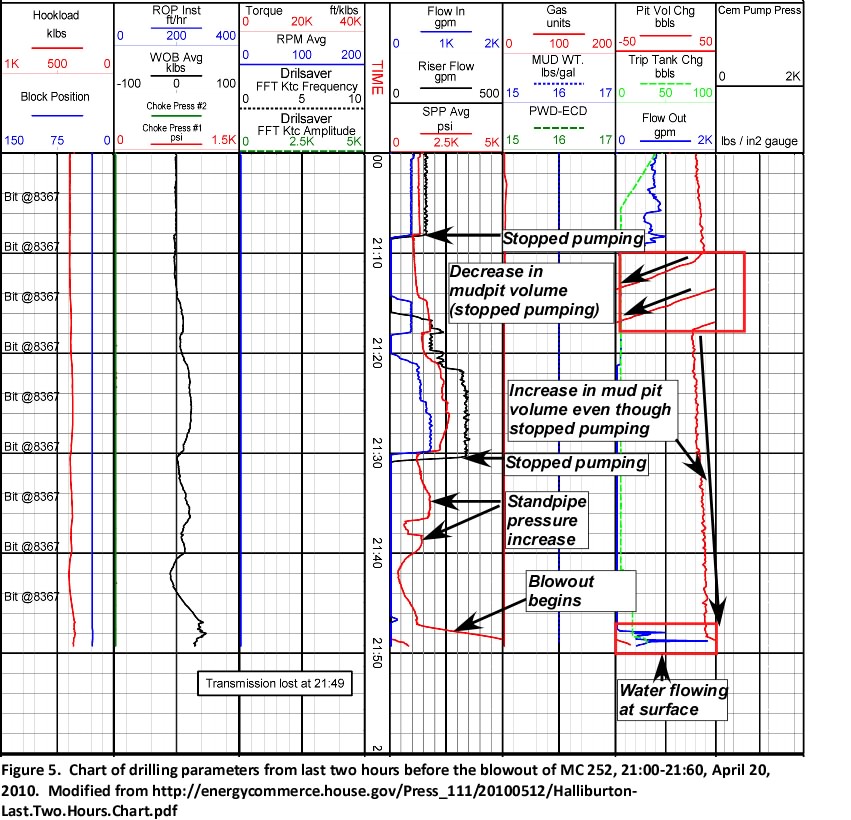

8. At 21:30, they stopped pumping again and circulated, but the pit volume continued to increase(Figure 5). Standpipe pressure increased and decreased twice between 21:30 and 21:42 (standpipe pressure generally reflects bottom hole pressure). This, along with a steady increase in mud pit volume, suggests that surges of gas were entering the drilling fluid from a gas column below the wellhead, and outside of the 7-inch production casing. Gas had probably channeled past the inadequate cement job near the bottom of the well and, by now, had reached the seals and pack-offs separating it from the riser at the sea floor.

9. At 21:47, the rate of standpipe pressure and mud pit volume went off scale, and water flow was measured at the surface. The blowout had begun.

Between 21:47 and 21:49 the gas behind the 7-inch production casing apparently overcame the wellhead seals and pack-offs that separated the wellbore from the riser. Almost instantaneously, the gas shot the water out of the riser and above the crown of the derrick. Then, the gas ignited and exploded.

I do not believe that there is sufficient and credible publicly available information to address those issues at this time. Based on the chronology presented above, it seems strange that so little was apparently done in the hour-and-forty minutes between the notable increase in mud pit volume and the blowout, except to stop pumping twice. At the same time, it is easy to see the warning signs now that we know the outcome, and we do not know what was done or discussed at the time--we only have recordings on a chart.

What can be addressed now is the larger issue that a flawed, risky well plan for the MC 252 well was approved by the MMS, and BP, Anadarko and Mitsui management. Similar or identical plans were undoubtedly approved and used by many operators on other wells drilled in the Gulf of Mexico. A plan that does not include enough cement to overlap the final and previous casing strings, and that does not require running a cement-bond log to ensure the integrity of the seal is a defective plan. The fact that there have not been blowouts on previous wells does not justify the approval and use of an unsafe plan.

Interior Secretary Salazar has announced a suspension of offshore drilling permits and an indefinite ban on new offshore drilling. This will have a profound economic impact on many thousands of rig and associated service jobs. The result will undoubtedly be new regulations. More regulation will accomplish little, however, if the underlying problem is a lack of critical thinking by the companies that drill oil and gas wells and the government agencies that oversee their activities.

In a few hours, they would have been ready to move the drilling rig off location so that a completion rig could move on. At about 10:00 p.m., the rig unexpectedly began to shake and a loud surging noise was accompanied by natural gas, drilling mud and sea water that shot high above the floor of the drill ship. The gas exploded and the rig was engulfed in flames. A second explosion followed and the electricity went out. Eleven men died instantly and 115 others rushed to the lifeboats or jumped into the Gulf of Mexico. This all happened so fast that those who died probably had no time to understand what was happening. Two days later, the Deepwater Horizon sank to the bottom of the Gulf of Mexico, and oil has been spilling into the Gulf at rates of at least 5,000 barrels per day since then(there are 42 gallons in a barrel).

The MC 252 well is located in 5,067 ft of water about 50 miles from the coast of Louisiana. The total depth of the well was 18,360 ft below sea level (13,293 ft below the sea floor). This is not an unusually deep well nor was it drilled in exceptionally deep water compared to many other wells in the Gulf of Mexico. The Gulf drilling depth record was set earlier this year at more than 30,000 ft below the sea floor (The Oil Drum, January 18, 2010: http://www.theoildrum.com/node/6135#more), and the current water-depth record of 10,011 ft was set in 2003 (http://www.deepwater.com/fw/main/Home-1.html).

Much information has surfaced since the accident through congressional and Mineral Management Service (MMS) hearings, public statements from the companies involved and, on May 16, a feature report on CBS Television’s Sixty Minutes program. Most of this information comes from eye-witness accounts by people on or near the Deepwater Horizon at the time of the blowout.

I consider most of the publicly available accounts so far to be potential hearsay although they probably contain some good observations and elements of truth. I discount the value of the testimonials chiefly because none of these people were on the rig floor at the time of the blowout. In addition, the only people who have a comprehensive and fact-based understanding of the events leading to the accident are either sequestered by the companies involved or are dead.

Chronology of the Disaster

1. The well had reached a depth of 13,293 ft below the sea floor. The final string of production casing from the wellhead at the sea floor to total depth had been put in the hole, and cemented in place on April 19, 2010.2. Only 51 barrels of cement were used according to the well plan. This was not sufficient to ensure a seal between the 7-inch production casing and the previously cemented 9 7/8-inch protection casing (Figure 2).

3. Mud had been lost to the reservoir while drilling the bottom portion of the well (this is called “lost circulation”). It usually indicates good reservoir quality, an interval of lower pressure or both, and can result in an enlarged wellbore or “washout”. The significance of this is that it might have been difficult to create a good cement seal between the casing and the formation. It also would have been impossible to ensure the effectiveness of the cement seal without running a cement-bond log, and this was not done.

4. The cement contained a nitrogen additive to make it lighter so that it would flow more easily and better fill the area between the casing and the lost circulation-washout zone. This also may have decreased its sealing effectiveness. Gas from the reservoir may have further diluted the viscosity of the cement.

5. While waiting approximately 20 hours for the cement to dry on April 20, the crew began displacing the drilling fluid (“mud”) in the wellbore and riser with sea water before setting a cement plug and moving off location. This mud was pumped into tanks at the surface, and then onto a platform supply vessel alongside the rig (whose captain gave testimony before an MMS hearing last week).

6. Sea water is much lighter than drilling mud so there was less downward force in the wellbore to balance the flow of gas from the reservoir. The drilling supervisors knew that there was gas in the drilling fluid because a gas flare can be seen in photos probably coming from a diverter line in the riser (Figure 3).

7. The chart of drilling parameters for the last two hours before the blowout suggests that the riser and upper 3,000 ft of the wellbore were fully displaced with seawater by 20:00 on April 20, and the crew was circulating the drilling fluid Beginning 10 minutes later, at 20:10, the mud pit volume began to increase probably because of gas influx (Figure 4). The volume increased so much, that the recorder re-zeroed four times. When the crew stopped pumping at 21:08, the mud pit volume decreased and this may have alleviated some concern about gas influx.

8. At 21:30, they stopped pumping again and circulated, but the pit volume continued to increase(Figure 5). Standpipe pressure increased and decreased twice between 21:30 and 21:42 (standpipe pressure generally reflects bottom hole pressure). This, along with a steady increase in mud pit volume, suggests that surges of gas were entering the drilling fluid from a gas column below the wellhead, and outside of the 7-inch production casing. Gas had probably channeled past the inadequate cement job near the bottom of the well and, by now, had reached the seals and pack-offs separating it from the riser at the sea floor.

9. At 21:47, the rate of standpipe pressure and mud pit volume went off scale, and water flow was measured at the surface. The blowout had begun.

Between 21:47 and 21:49 the gas behind the 7-inch production casing apparently overcame the wellhead seals and pack-offs that separated the wellbore from the riser. Almost instantaneously, the gas shot the water out of the riser and above the crown of the derrick. Then, the gas ignited and exploded.

Issues That Can and Cannot Be Addressed

There are many disturbing issues raised by the MC 252 well blowout. The Sixty Minutes report leaves the impression that there were clear indications of things that went wrong in the weeks leading up to the blowout. It further implies that BP and the other companies involved with the drilling operation ignored these problems in the interest of saving time and money.I do not believe that there is sufficient and credible publicly available information to address those issues at this time. Based on the chronology presented above, it seems strange that so little was apparently done in the hour-and-forty minutes between the notable increase in mud pit volume and the blowout, except to stop pumping twice. At the same time, it is easy to see the warning signs now that we know the outcome, and we do not know what was done or discussed at the time--we only have recordings on a chart.

What can be addressed now is the larger issue that a flawed, risky well plan for the MC 252 well was approved by the MMS, and BP, Anadarko and Mitsui management. Similar or identical plans were undoubtedly approved and used by many operators on other wells drilled in the Gulf of Mexico. A plan that does not include enough cement to overlap the final and previous casing strings, and that does not require running a cement-bond log to ensure the integrity of the seal is a defective plan. The fact that there have not been blowouts on previous wells does not justify the approval and use of an unsafe plan.

Interior Secretary Salazar has announced a suspension of offshore drilling permits and an indefinite ban on new offshore drilling. This will have a profound economic impact on many thousands of rig and associated service jobs. The result will undoubtedly be new regulations. More regulation will accomplish little, however, if the underlying problem is a lack of critical thinking by the companies that drill oil and gas wells and the government agencies that oversee their activities.

2 comments:

Though I had no experience on industrial construction projects, I ran in fear after only a few months working on Oregon's Trojan Nuclear plant and on the Pumping Station Modules for The Alaskan Pipeline. The standard attitude was, "Once done, out of sight, out of mind."

Only money for their families mattered. This is, by definition, a stupid attitude, though typical.Now look.

Totally agree with you. There has been a mentality is morally corrupt. I believe that the gulf blowout will change all that - though in far off places around the the world, the attitude will likely prevail, which is sad and profoundly distressing to me - I hope there comes a time sooner than later that we more fully recognize the limitations of our current approach to managing our environmental resources.

Post a Comment